“We based our purchase decision on the experiences of other customers who told us that Nikon’s products provide effective quality control solutions.”

At the Berlin plant of Feuerstein GmbH (www.feuerstein-needles.de), a leading German manufacturer of surgical needles and precision parts for the medical industry, a true revolution in product inspection took place. They replaced two systems, an older optical CNC measuring system and a digital projector, which were too slow to handle the large volume of parts. They were replaced in 2020 by a VMZ-R3020* CNC video measuring system from Nikon Metrology.

Ruben Weiss, project manager at Feuerstein, explains: “The main reasons for investing in this new testing methodology were the reliability of the method and the possibility of obtaining detailed measurement results according to geometric specifications.”

He also explained the significant benefits of using the new Nikon Metrology device. The first advantage is the automated and digital control, which allows complete traceability of the results. The measurement cycle time per 100 needles could be more than halved, which leads to higher efficiency in the quality department and significantly improved monitoring of production processes. In addition, the rejects have been reduced by about 10 percent due to the high accuracy.

The collected data is transferred in real time, e.g. to an Excel spreadsheet, which enables traceability as well as simple operation and high precision in the measurement of the smallest geometries.

Feuerstein manufactures surgical needles, atraumatic needles, suture material, drainage needles and other precision parts as well as custom-made products to the highest quality standards. For over 50 years, the company has been supplying products to customers in over 40 countries. The needles are mainly made of stainless steel, but also of tungsten, which must be inspected with particular care due to their extremely precise tolerances and geometries, including a tip with a radius of less than 5 microns. The dimensions must be guaranteed and traceable.

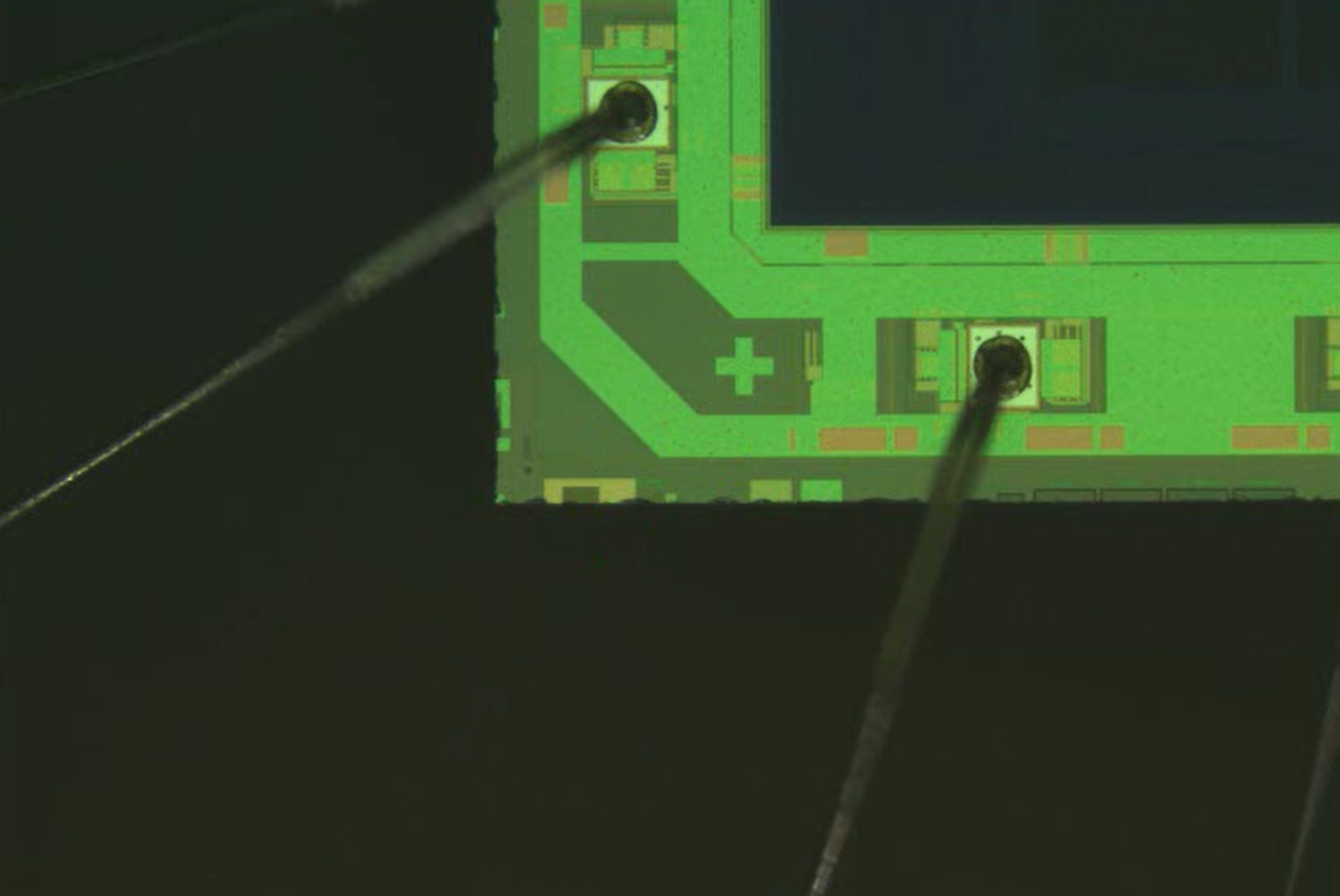

The VMZ-R3020 Type 4 CNC video measurement system supplied by Nikon Metrology has a working range of 300 x 200 x 200 mm, equipped with a high-res XGA-CMOS camera, high-quality optics and a TTL-Laser autofocus (Through the lens). In conjunction with the NEXIV AutoMeasure software for vision measurement and image processing, the system offers quick and automatic video edge detection for a fast and reliable measurement process. NIKON-made Linear Encoders with a high resolution of 0.01µm report the position of all 3 axes (XYZ) back to the controller, ensuring the accuracy resulting in a maximum error of 1.6µm per 100mm.

The extremely fast 5-step zoom with 15x zoom optics offers a wide field of view at low magnification as well as an outstanding resolution at high magnification, due to the high numerical aperture, so that even the finest structures can be reliably measured. 8-segment ring illumination as well as reflected and transmitted light combined with the high-quality optics manufactured by Nikon facilitate the accurate detection of low-contrast features. Nikon’s intuitive software enables efficient and fast program creation.

“We based our purchase decision on the experiences of other customers who told us that Nikon’s products provide effective quality control solutions.”

Mr. Weiss added: “The training provided by Nikon Metrology after installing the video inspection machine was professional, well thought out, helpful, friendly, solution-oriented and straightforward and is therefore particularly noteworthy.

We have full confidence in the device’s ability to provide fast, accurate and reproducible measurements for quality control and for optimizing production processes, both for our existing product range and for others we will introduce in the future.”

* VMZ-R has been discontinued. Please check our new NEXIV VMZ-S Series

NEXIV VMZ-S Series video measuring systems delivers high accuracy, speed and usability for inspection applications down to the micro level.

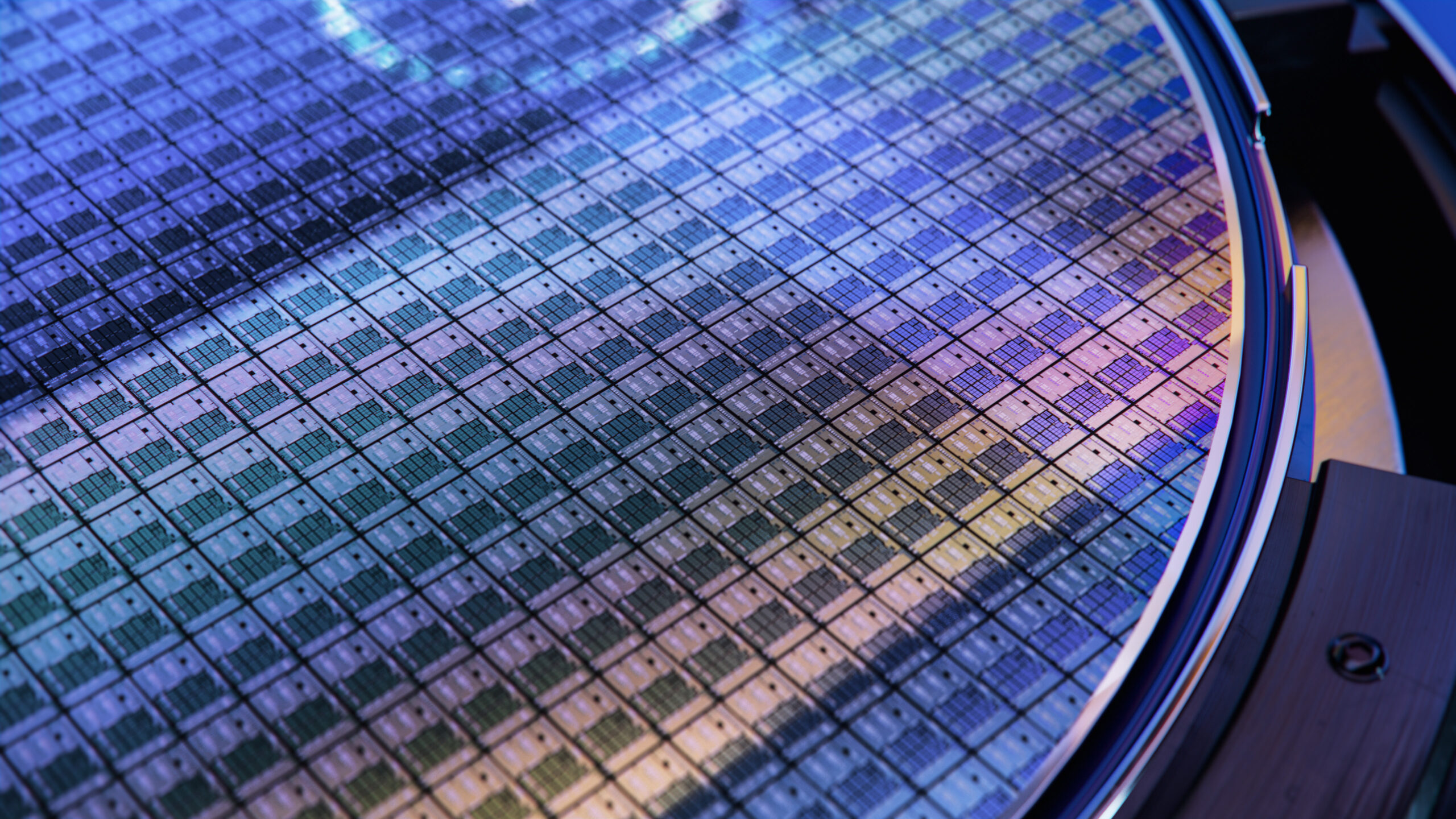

It can be used to measure various samples in the expanding market of in-vehicle electronic components and semiconductors, as well as in precision machined and molded parts.

Core features:

• Capable of high resolutions at long working distance

• Wide ranging zoom optics streamline dimensional measurements

• Excellent accuracy within field of view

• High accuracy, high speed measurement with through the lens (TTL) laser AF

• Lighting systems capable of reliably detecting all shapes