Between 1st May, 2019 and 30th April, 2022, the University of Eastern Finland established Tomolab, a new X-ray CT (computed tomography) laboratory, with the strategic aim of supporting research, development, innovation and educational projects in the area.

Although the university had already acquired a small X-ray machine in 2006, more powerful equipment was needed to investigate denser materials, including metals, with sufficient capacity to examine a wider spread of sample sizes – from an ant’s head to a basketball-size object weighing up to 15 kg. After researching the market, four possible suppliers were shortlisted. Their equipment was benchmarked by scanning a weld joint in a steel cylinder, a bone cartilage sample, and a piece of cardboard.

Based on the results, the team purchased an XT H 225 micro-focus X-ray CT system from the Nikon Industrial Metrology Business Unit (https://industry.nikon.com). The installation marks an important strengthening of the FinTomo network, founded in 2017 to improve communication and sharing of information between Finnish tomography laboratories. The idea is to expand the use of CT equipment nationally and avoid overlap of resources.

The Tomolab project was implemented not only by the University of Eastern Finland, but by Savonia University of Applied Sciences, Savo Consortium for Education, and the Natural Resources Institute of Finland (Luke). The Nikon equipment is located in SIB Labs (www.uef.fi/en/unit/sib-labs), a research unit operating in the Faculty of Science and Forestry within the university. Key operations carried out by the faculty’s 200+ multi-disciplinary scientists focus on transferring scientific expertise, and providing services to customers in research, business and academia. The two main activities are imaging, including electron microscopy and microspectroscopy, in addition to X-ray CT; and materials testing and structural analysis.

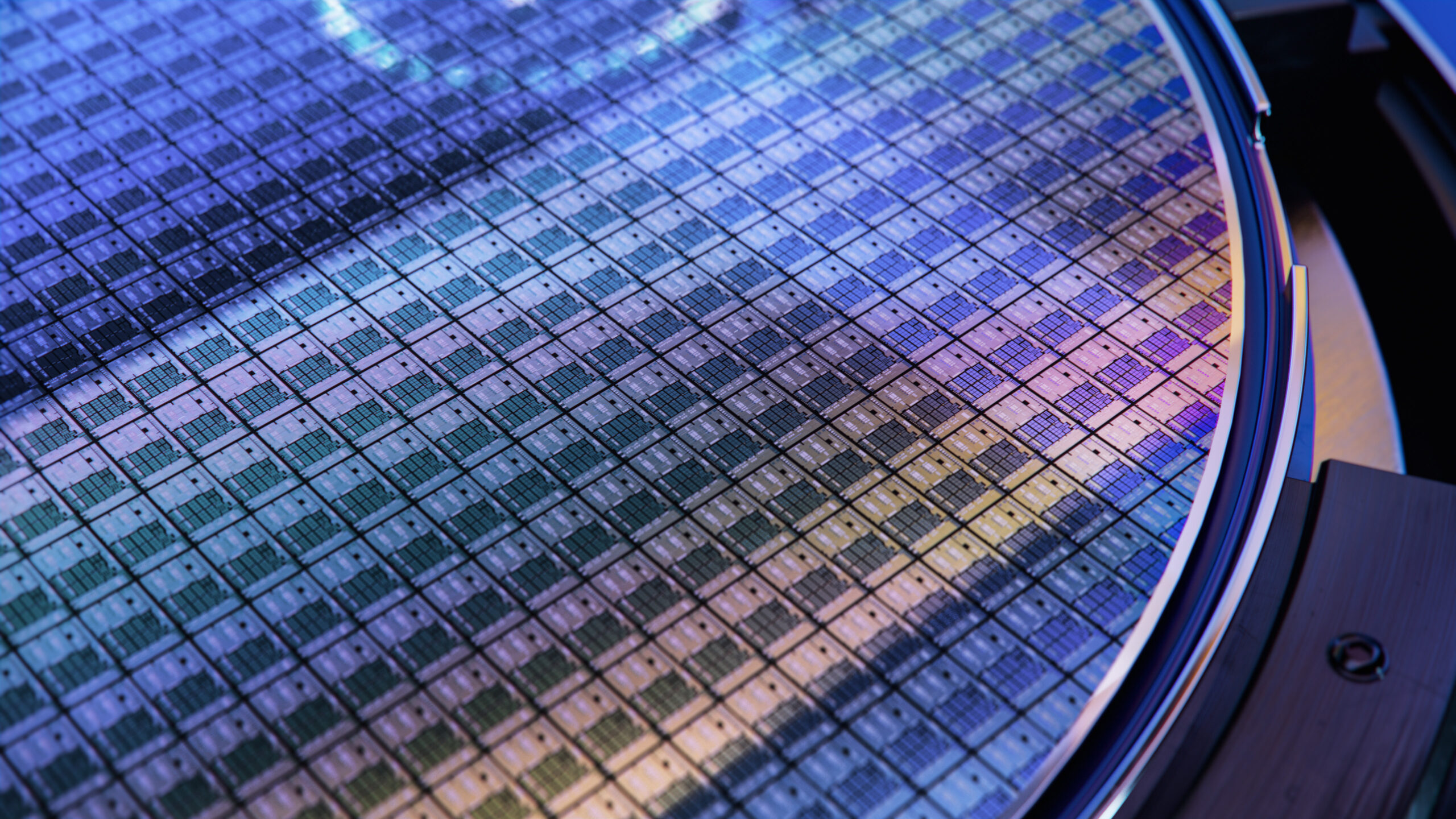

Pilot projects carried out so far have been conducted in three areas. One is biological and biomedical research, analysing the structure of animal and human tissues including articular cartilage, bone, cochlear implants, teeth and dental implants; there has also been a focus on plants, including cereal grains, pine seeds and potato root systems. The advantages of X-ray CT here include the ability to measure radiation doses of scans, and determine how this irradiation affects the germination percentage of pine seeds. A second activity involving X-ray CT includes investigation into composite materials and tools to support plastic and metal 3D printing. The third area is failure analysis of metals by observing internal and external defects in components and weld seams. This also encompasses structure and morphology examination, damage investigation, quality control, modelling and augmented reality.

The University of Eastern Finland has campuses in two Finnish cities, Joensuu and Kuopio, a city and municipality in the region of Northern Savonia. In Kuopio the campus is in Savilahti, an area about two kilometres west of the centre. It is located on the science and research park, which remarkably is host to more than 200 companies and academic establishments. Half of the students from the University of Eastern Finland and about two-thirds of the staff are located there. The new Tomolab project also links in the activities of the Microsurgery Centre of Finland in Kuopio University Hospital, as well as the surrounding area where many of the hundred or so local businesses and communities are involved in 3D-printing research, development and application. Additionally, services are provided to many units within Luke, for example the collaboration with its centre in Oulu for the study of foodstuffs and plant diseases.

Fascinating project furthers understanding of cochlear implantology

As an illustration of the advanced capabilities that the Nikon X-ray CT system brings to Savilahti, SIB Labs researcher Tuomo Silvast and Matti Iso-Mustajärvi, an ear, nose and throat (ENT) specialist working in the Microsurgery Centre at Kuopio University Hospital, reported on the results of a recent research project. Supported by a research group headed by Docent Aarno Dietz, an ENT consultant and head of department, it was aimed at helping the profoundly deaf to hear by identifying the optimum method for implanting a cochlear electrode into the inner ear.

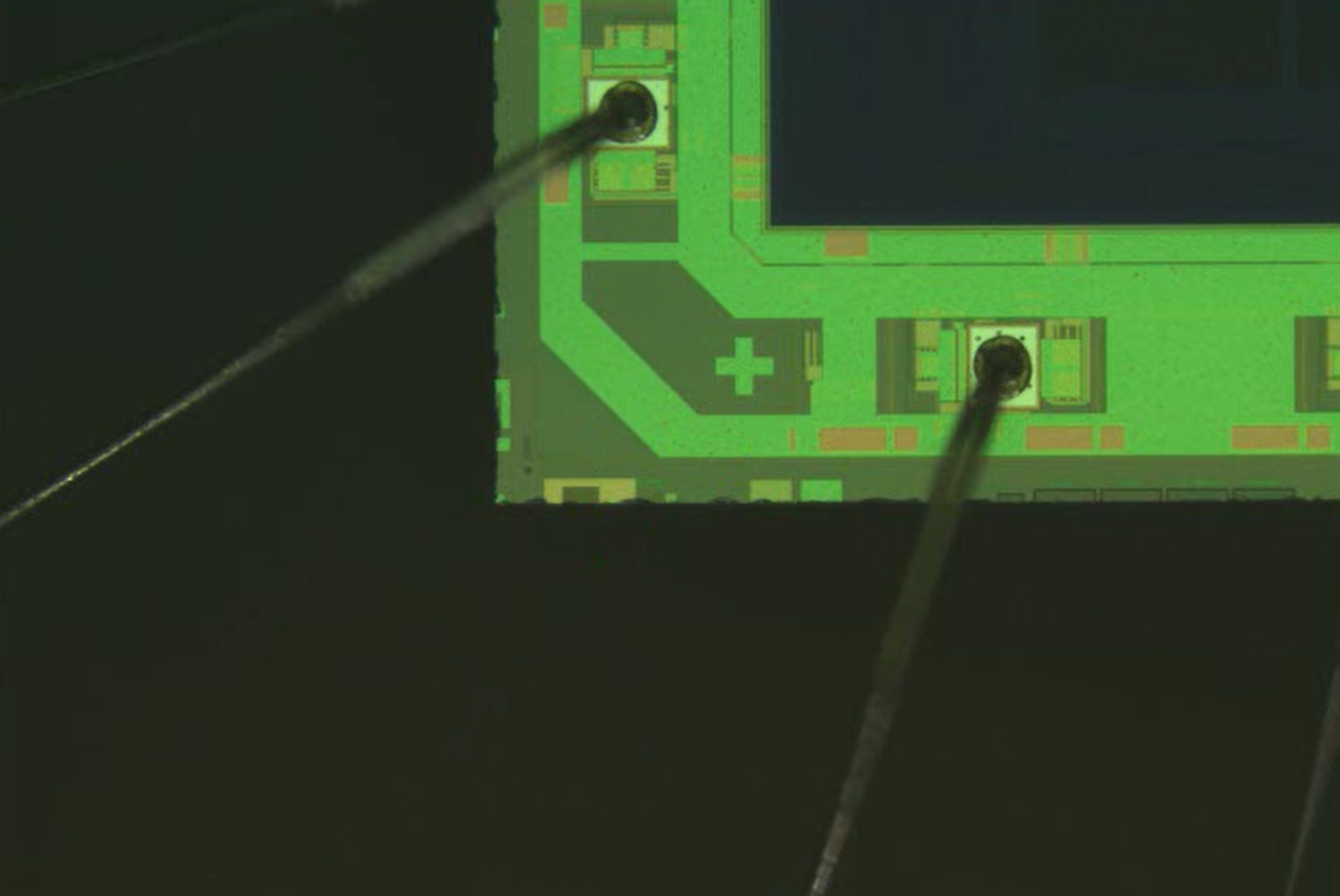

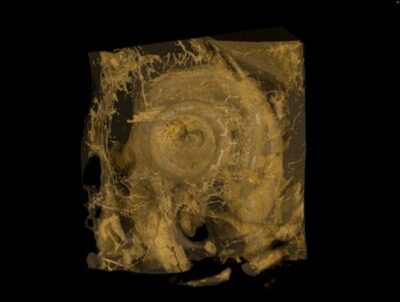

After a proposed new surgical technique had been performed on a portion of temporal bone containing the ear of a cadaver, X-ray tomography examination was able to establish the exact positioning of the electrode array. Specifically, it was important to determine whether its placement had breached the basilar membrane inside the cochlea, as such trauma would adversely affect the implant’s ability to help a patient to hear.

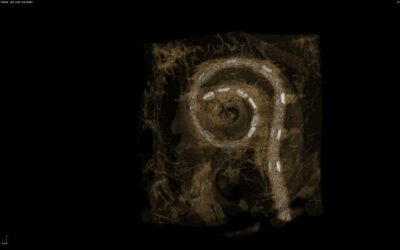

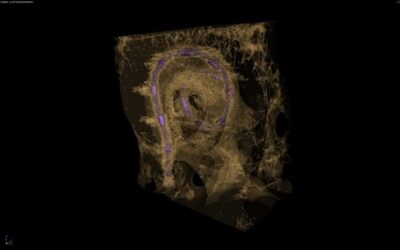

Figure 1: 3D visualisation of the scan data show the positions of the electrode contacts inside the cochlea as well as the insertion depth, which are both important issues in implant positioning.

Commensurate with the density of human bone, imaging parameters chosen in the Nikon XT H 225 were 150 kV / 7 watts, a 0.1 mm aluminium filter and 15 micron pixel size. 4476 X-ray projections over one full resolution of the sample in 20 minutes produced 68 GB of data that was reconstructed to produce a high-quality 3D tomogram.

“The benefit of X-ray CT is that it is easy to view the inner ear from any direction, which is a big advantage over traditional histological techniques involving sectioning a specimen and viewing a sample under a microscope.

Matti Iso-Mustajärvi, Ear, Nose and Throat (ENT) Specialist, Microsurgery Centre, Kuopio University Hospital

“Histology is rather expensive – there are many work phases to be carried out manually and it is time consuming. Moreover, histological samples are limited to one plane of view only.

“I made my own STL files for the bone element of the tomogram and for the electrode. They were assigned their own colours and transparencies and merged into the same 3D image to enable clearer viewing of, for example, the position of the electrode wires in relation to the interscalar septum of the cochlea.”

He pointed out that trials had been carried out using clinical cone-beam computed tomography, but it is less accurate in trauma evaluation. For future electrode studies, the Nikon equipment will be able to fit the whole sample including the temporal bone inside the machine to avoid unnecessary manipulation of the sample. From the final images, the position of different electrodes in relation to the basilar membrane inside the cochlea will be visible and easy to interpret. It will therefore be possible to determine whether there has been lifting or rupturing of the basilar membrane or full translocation of the electrode through it.

Mr Iso-Mustajärvi confirmed that results are obtained quickly, with good image quality, and that the 3D constructions enable deeper understanding of electrode interaction with individual cochlear anatomies. Regarding the efficiency of the X-ray scanning, a test carried out in the laboratory comparing the pre-existing X-ray CT system with the Nikon equipment, both set to 100 kV, 10 W, demonstrated a dramatic uplift in efficiency. The XT H imaged a cochlear sample rotated through 360 degrees in one hour, whereas the smaller machine took eight hours to generate projections through only half a turn.

The Nikon XT H 225 micro-focus X-ray CT system

Mr Silvast advised that the X-ray CT system procurement went well from the initial stages and the new equipment was ready for use in March 2020, 10 months after the start of the project – the delay being due to Covid-19.

We opted for the Nikon solution because we needed more power for faster scanning, the ability to scan bigger samples, and a small voxel size of 1 micron all rolled into one. It was the best choice for us out of the four systems evaluated.

Tuomo Silvast, SIB Labs Researcher, Microsurgery Centre, Kuopio University Hospital

“Commissioning included installation, testing and calibration of the equipment. It was followed by five days’ training from Nikon engineers, which was very useful. Answers to our questions about the device and software were, and still are, prompt and informative.

“We now scan samples for different departments within the university, for commercial companies and for our research collaborators. We also instruct researchers to use our instruments independently.”

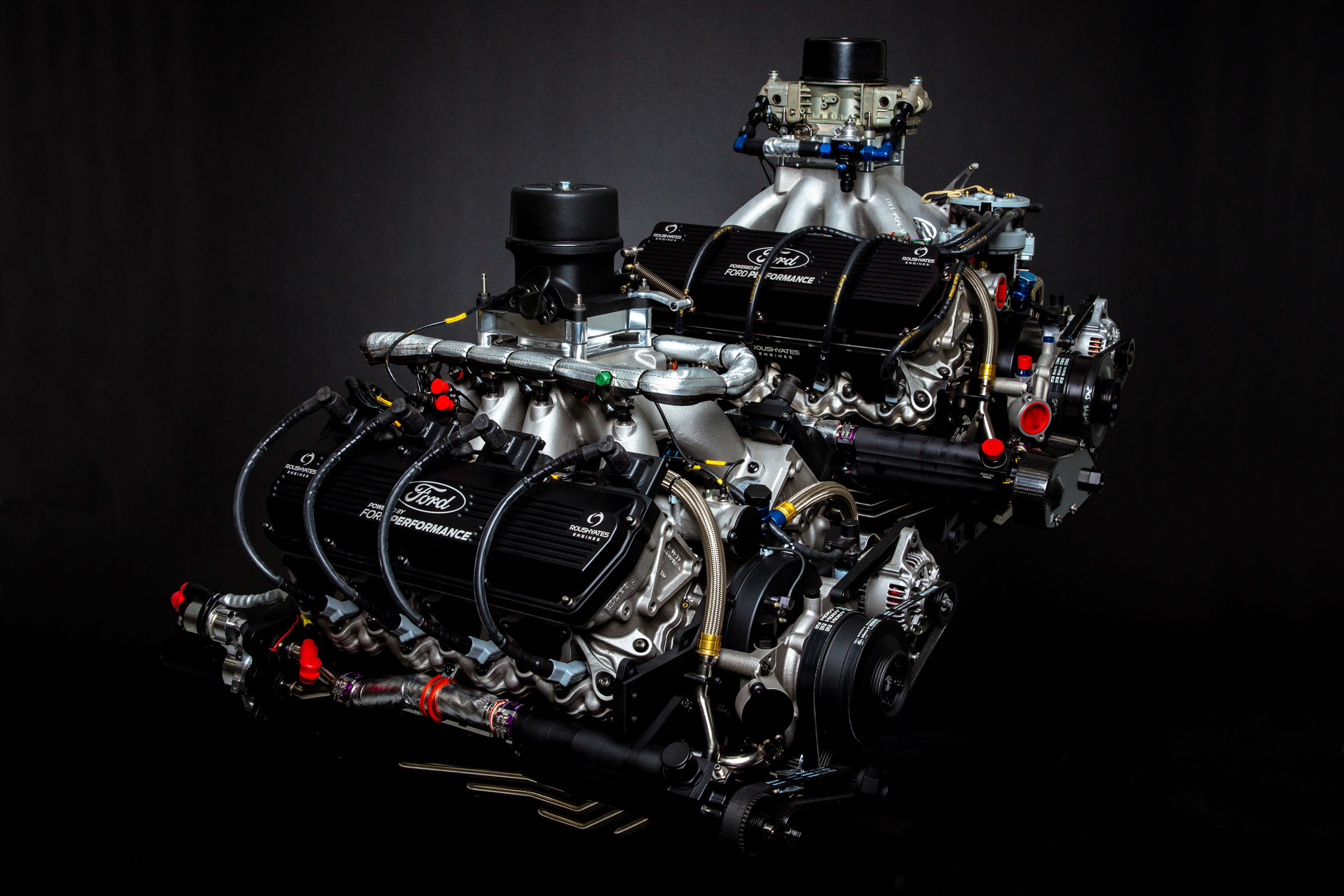

The Nikon micro-CT machine combines a 225 kV source with a small X‐ray focal spot size, delivering sharp images with minimal noise. It uses the manufacturer’s Inspect-X software, an advanced graphical user interface providing intuitive workflow that can be tailored to SIB Labs’ applications. Coupled with rapid reconstruction times using a Nikon algorithm written in-house, and cutting-edge visualisation and analysis software, the XT H series is a comprehensive package for inspection and measurement.

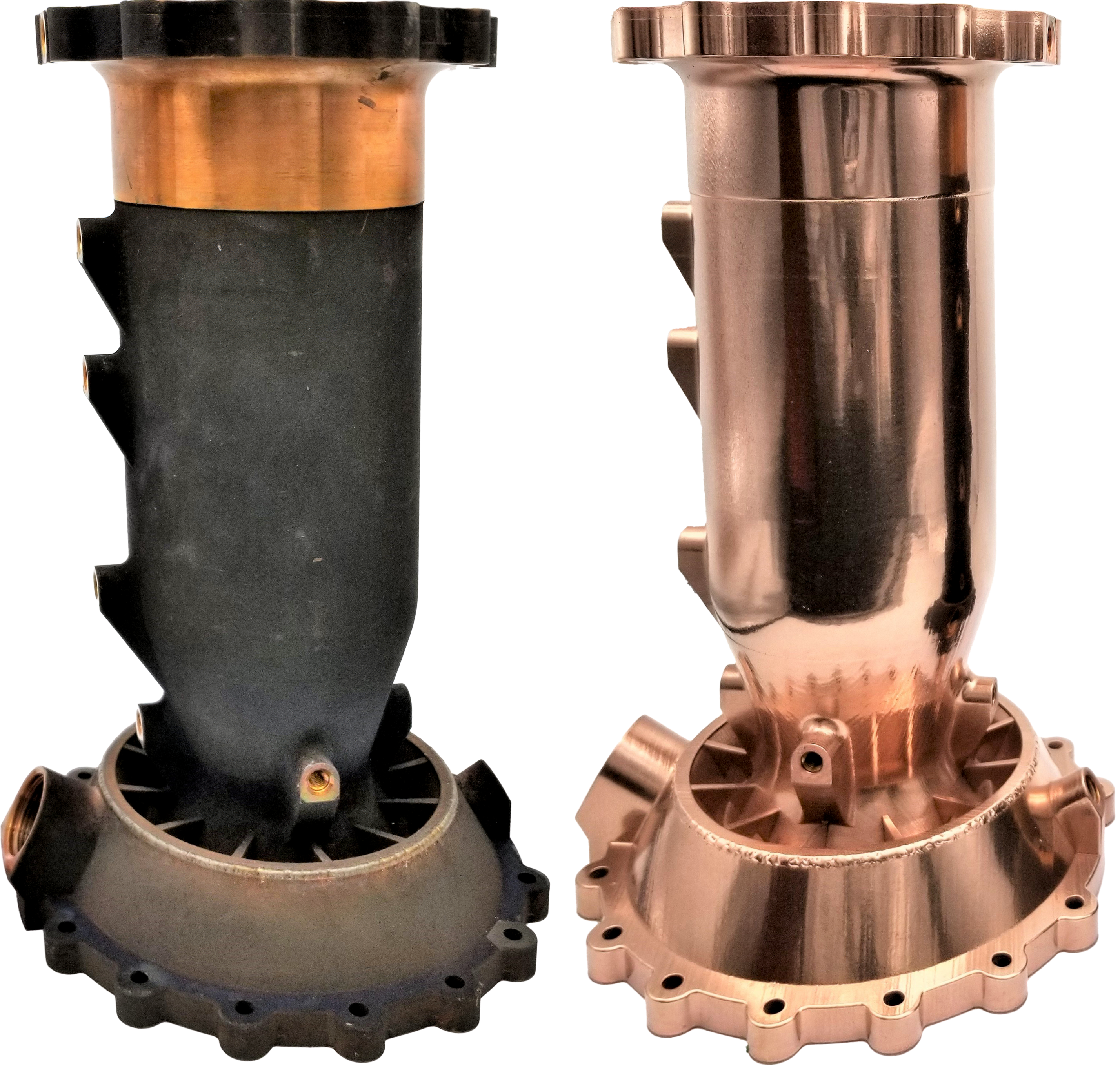

One of the main advantages of Nikon Metrology’s open-tube micro-CT system, apart from the small focal spot size, is the ability to quickly exchange the target that electrons impinge on to generate X-rays. The machine in Savilahti has a 180 kV transmission target and a 225 kV multi-metal reflection target that is swappable between tungsten, molybdenum, copper and silver. Molybdenum is ideal for studying delicate specimens and all targets may be exchanged without breaking the vacuum in the source tube.

Motorised FID (Focal spot to Imager Distance) allows the detector to move closer to the source to prevent the X-ray flux from decreasing, resulting in faster scan times or brighter images. The machine specification includes X-Tend helical scanning acquisition and reconstruction software for capturing high-resolution images of tall samples spanning multiple fields of view, a feature that Mr Silvast describes as unexpectedly practicable and fast.

In 2023, SIB Labs will continue to strengthen the imaging continuum of the Savilahti region when the university starts the training of masters in the field of technology in Eastern Finland. The education programme covers X-ray CT in materials science, medical physics and technology, and industrial applications. It will include measurement of shape, volume and surface area; fissure, porosity and inclusion analysis; fibre composite analysis; reverse-engineering; and CAD-to-part comparisons based on scan data.

Mr Silvast concluded that the Nikon XT H technology implemented in this project is highly versatile and future-proof owing to the replaceable filament, target and detector, and can be widely applied to the needs of many organisations in the region. He also stressed that the 3D imagery generated is highly effective, not only in research and industry but also for teaching programmes in the local universities and vocational colleges.

Figure 2: Slice images reveal the location of the electrode in relation to the basilar membrane (interscalar septum as used above) inside the cochlea. Preservation of the intracochlear structures is crucial for hearing preservation, and is related to overall better hearing results after surgery.