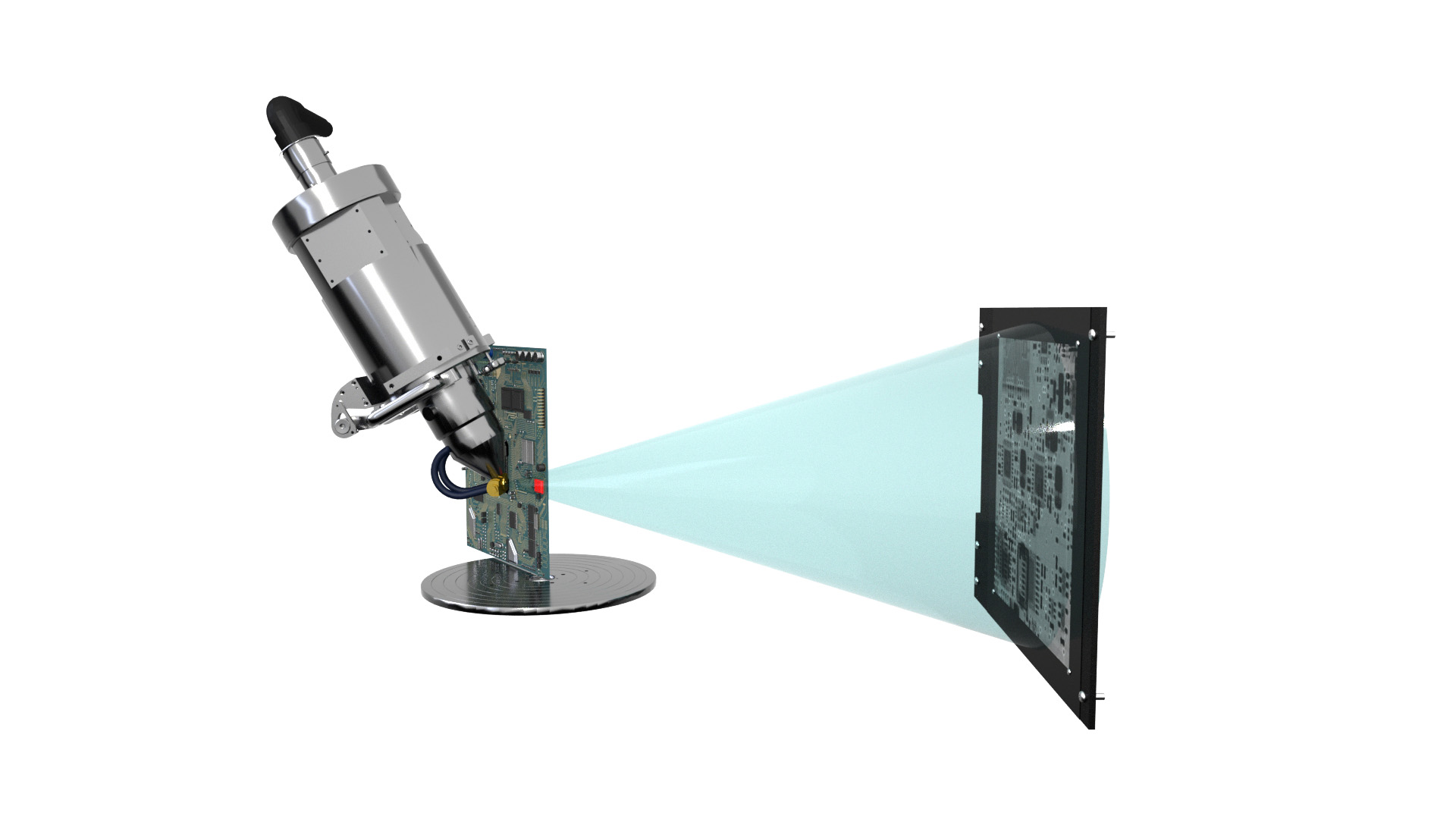

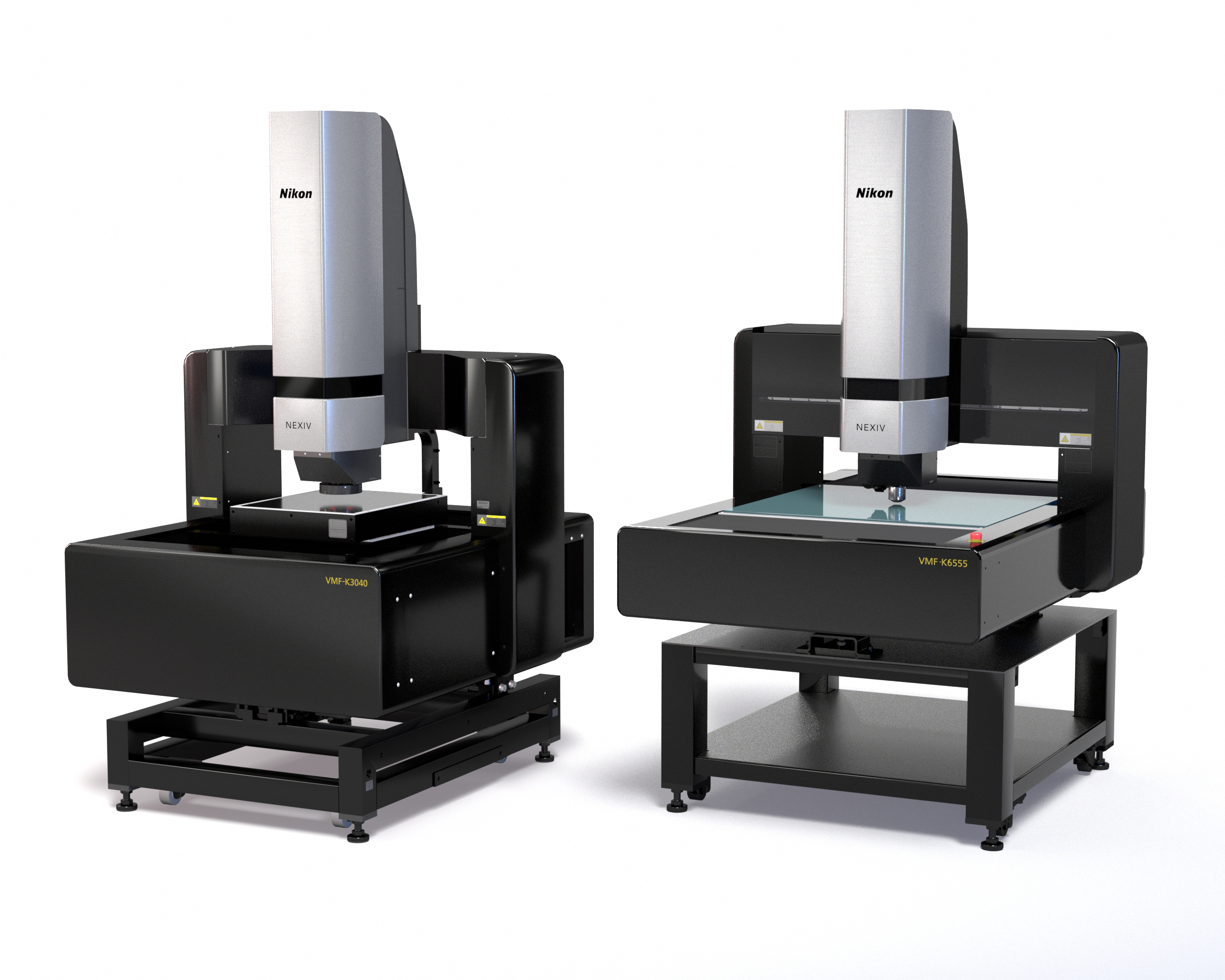

Nikon Industrial Metrology presents an exciting new metrology system for manufacturers seeking to measure the geometry of medium-to-large parts – from a car door, casting or fabrication to a whole car chassis or airframe structure. APDIS Intelligent Quality (IQ) Stations offer a range of Laser Radar solutions as alternatives to traditional, slow, monolithic, inflexible panel machines and large-volume, horizontal-arm CMMs.

Nikon’s non-contact Laser Radars are already used by major OEMs on a global scale to measure thousands of parts every day, both in metrology rooms and on shop floors”, reports Paul Lightowler, APDIS Global Product Manager. “APDIS IQ Stations now provide complete turnkey solutions from Nikon, utilising the speed and data quality improvements of the latest-generation MV430E Laser Radar to give fully automated measurement stations that are simple to program, fast to measure and flexible to install.”

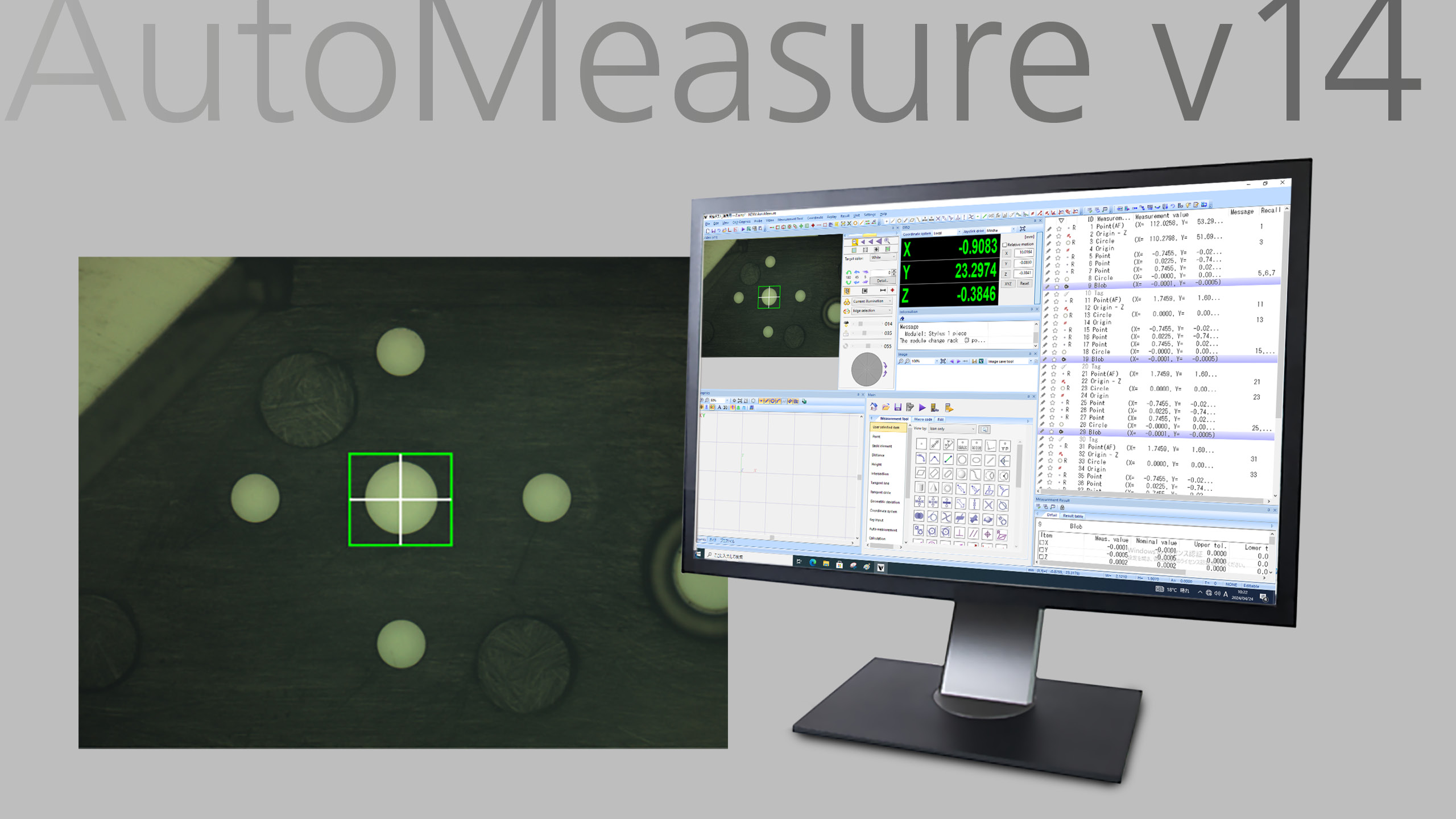

The use of a predefined set of positions eliminates the requirement for robot programming following installation, even when modifying measurements or adding new parts. Measurement program analysis is achieved with a few simple clicks, enhanced by the ability to define and simulate measurements off-line prior to physical setup.

Measurement routines are selected via the inbuilt HMI, so all that’s required is to load a part and click a button. Direct feature measurements remove the need for adapters, while small data sets drive faster analysis, speeding up pre- and post-measurement times.

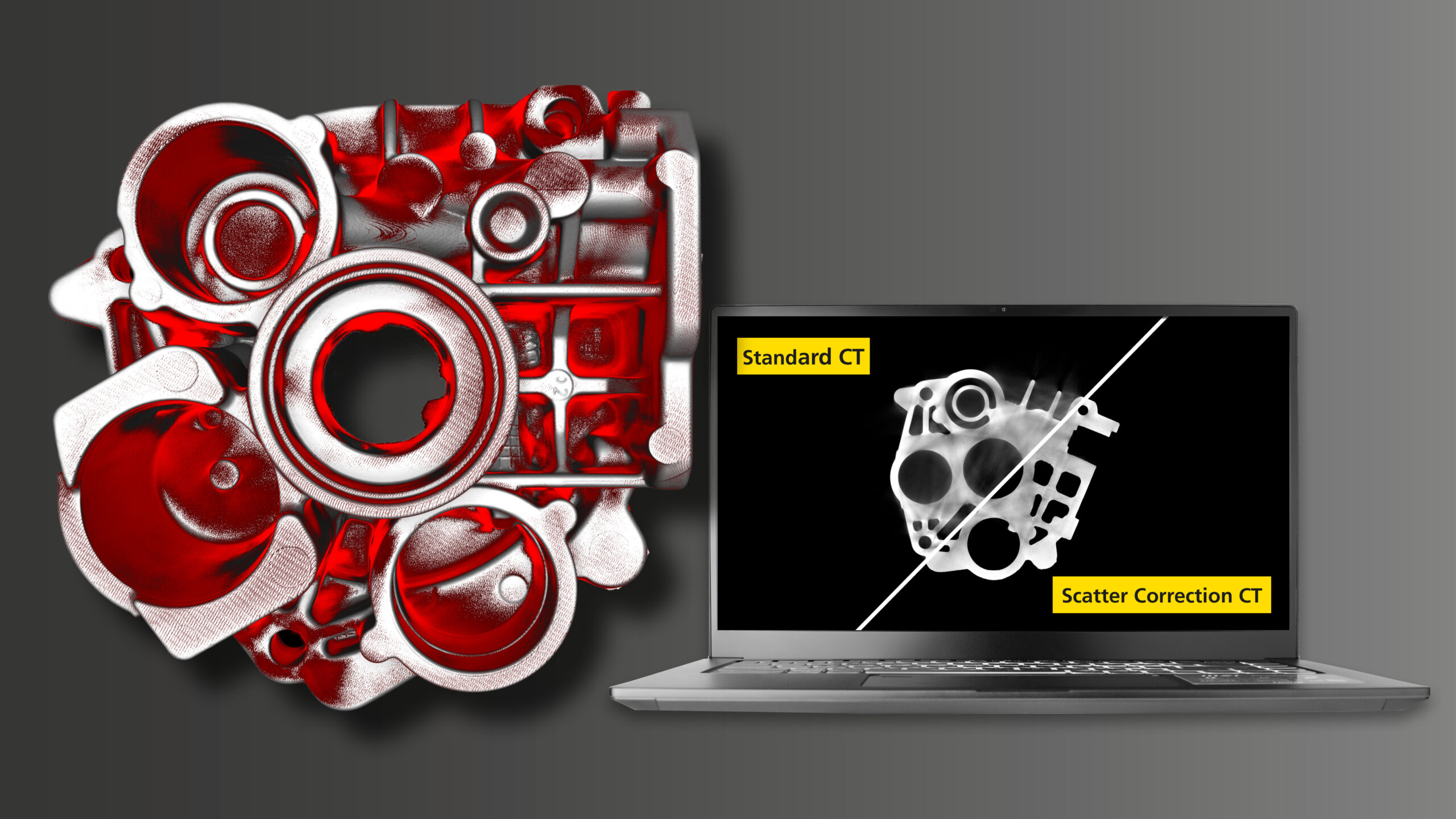

Intelligent Quality means a smart, efficient and productive form of measurement, irrespective of a component’s colour or surface finish. Therefore, the bottlenecks of traditional CMMs are removed, resulting in faster analysis and more data for improved process quality.

The automated turnkey IQ Stations are fast to install, configure and commission, while simplified programming and modification deliver flexibility and ease of use. Measurements may be made by choosing routines based on preset robot locations and defined turntable positions, further reducing inspection and analysis times.

Four robotic APDIS IQ stations are available, depending on part size and measurement requirements; from single Laser Radar and turntable setups, to dual Laser Radar and robot setups for ultimate measurement productivity. Each is a turnkey configuration that has been designed in response to customer feedback. Nikon supplies, installs and commissions the measuring stations as well as providing programs, training and after-sales support. Please see further information: APDIS IQ stations

Nikon provides a variety of products, services, and solutions worldwide, based on advanced opto-electronics and precision technologies cultivated during the company’s more than 100 years of history. The group continues to create new values that contribute to improvement of quality of life and manufacturing in a wide variety of forms. Nikon’s Industrial Metrology Business Unit (IMBU) delivers integrated, optimised, ultra-high precision solutions that are not only customised and cost-effective but also work extremely well as soon as they are implemented.

On behalf of:

Nikon Metrology

Interleuvenlaan 86, B-3001 Leuven, Belgium.

Contact: Leonie Hofmann, Laser Radar & Laser Scanner Marketing Manager Europe

Tel: +49 160 94490183

Email: [email protected]

Web: www.industry.nikon.com

Issued by:

The Right Image Ltd

PO Box 42, Twickenham, TW1 1BQ

Tel: +44 (0)20 8891 0603

Contact: Chris Wright

Email: [email protected]

Web: https://www.therightimage.net