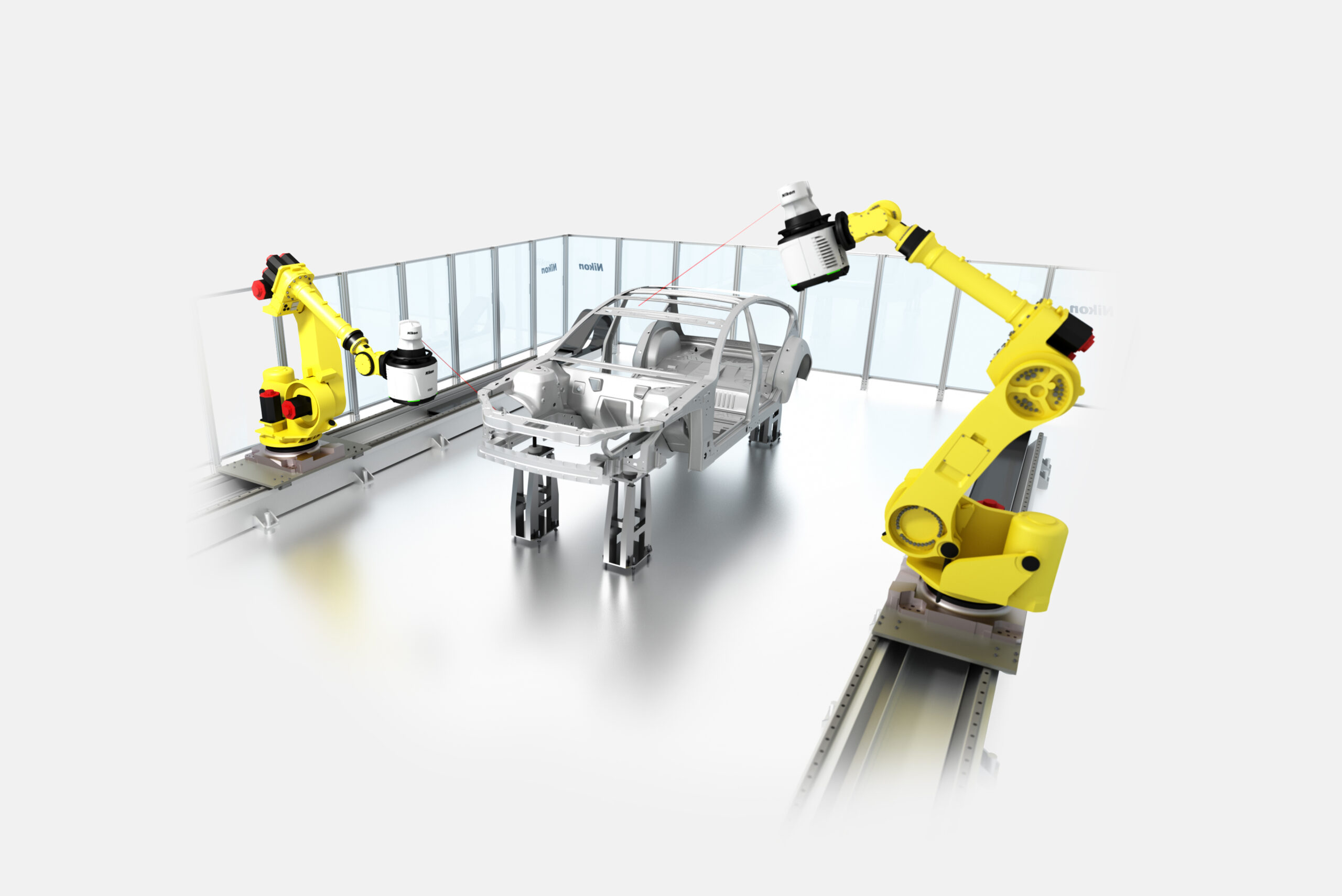

Nikon IMBU (https://industry.nikon.com) and Applied Automation Technologies (AAT3D) have announced the successful integration of Nikon’s LC15Dx wireless non-contact laser scanner with AAT3D’s CAPPSNC on-machine metrology software. This innovative combination enables the seamless integration of non-contact inspection within the machine tool envelope while providing wireless data transfer, unlocking a new era of manufacturing efficiency and quality assurance.

“The pairing of Nikon’s laser scanner with AAT3D’s CAPPSNC software is a game-changer for manufacturing processes,” said Nikon Product Manager Kristof Peeters. “We find ourselves at an exciting inflection point where connected machines, big data analytics, and automation intersect to bring unprecedented efficiencies. The solution Nikon has created with AAT3D enables manufacturers to gather more data, inspect more complex parts, and achieve tighter tolerances, all of which greatly improves production efficiency.”

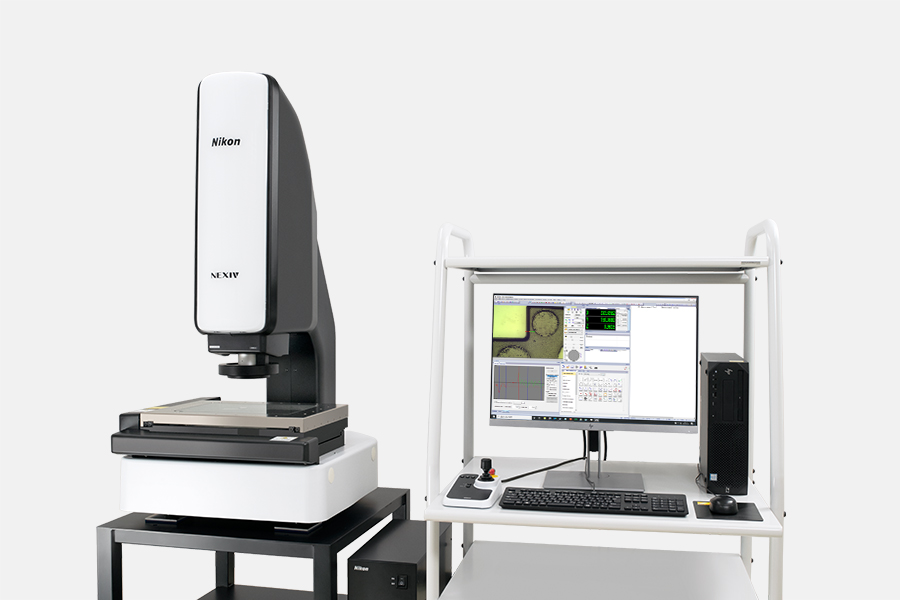

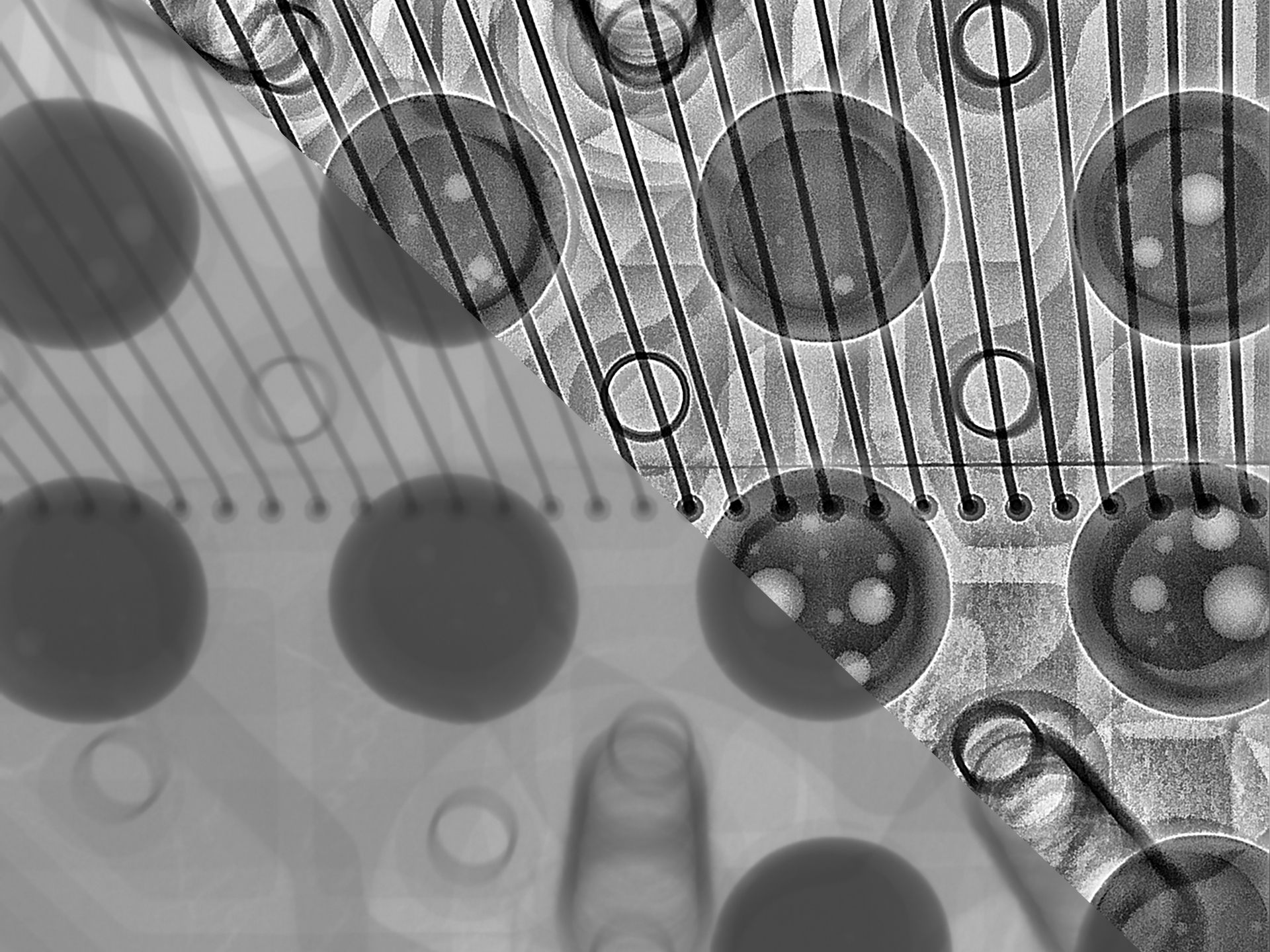

The Nikon LC15Dx wireless laser scanner boasts exceptional accuracy and speed, can capture detailed 3D point clouds of parts with micron-level precision and was developed to meet the more complex metrology demands of Industry 4.0 and shopfloor environments. Its wireless data transmission eliminates the need for cables, ensuring seamless integration and flexibility within the machine tool environment.

“Data is king in today’s manufacturing environment, and the ability to gather and analyse real-time data directly at the point of production is crucial for achieving the highest levels of quality and efficiency,” said Ray Karadayi, CEO of AAT3D. “Our collaboration with Nikon brings together two industry leaders in non-contact inspection technology and processes to deliver a solution that redefines the possibilities for in-process metrology.”

Nikon released its wireless laser scanning technology in 2023 to enable manufacturers to move their inspection processes onto the shop floor. The first customer installation of the Nikon LC15Dx wireless laser scanner with CAPPSNC software occurred at the end of 2023. This groundbreaking technology is poised to revolutionise the in-process metrology landscape, setting a new benchmark for quality and efficiency in manufacturing environments worldwide.

With this integration, AAT3D expands its reach in CNC in-process inspection, leveraging its expertise in non-contact laser devices and extending the capabilities of CAPPSNC software to a broader range of applications and CNC types. This will empower manufacturers to minimise setup times, control in-process machining, gather tens of thousands more data points for quality reporting, and inspect details that may be too small or too challenging for traditional touch probe routines.

About Nikon Corporation

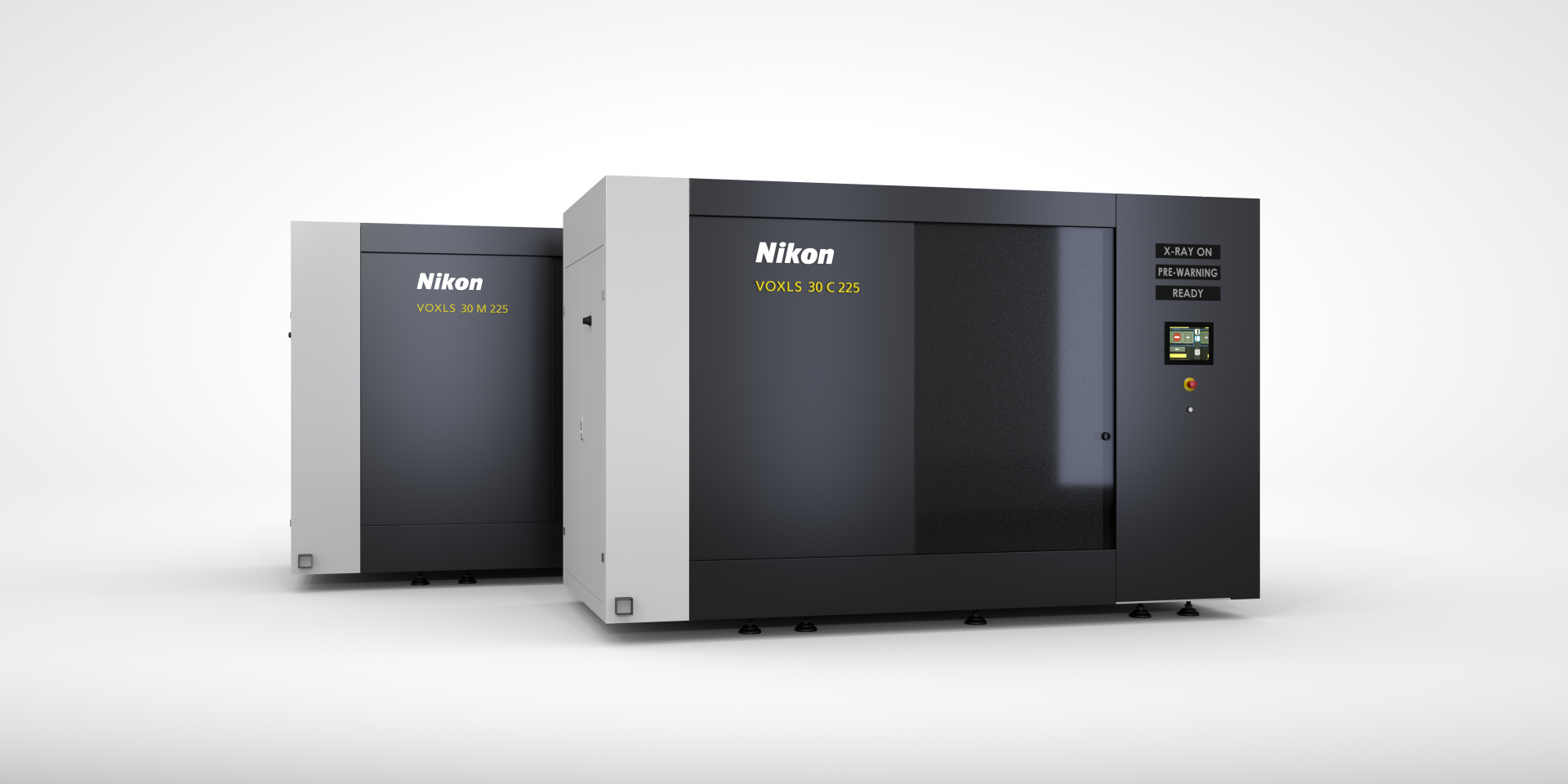

Nikon has been a pioneer in optical technology markets worldwide since its inception in 1917. Today, utilising advanced technologies, Nikon offers a wide range of products and solutions, from digital cameras and binoculars to industrial precision equipment such as FPD and semiconductor lithography systems, microscopes, measuring instruments, and products for the healthcare field. In the future, Nikon will take advantage of the company’s core technologies to generate new core pillars of profit, including the material processing business; Nikon strives to sustainably grow its enterprise value in the medium- to long-term.

About Applied Automation Technologies (AAT3D)

AAT3D is a leading provider of in-process metrology solutions for the manufacturing industry and dimensional measurement since 1987. The company’s innovative technology enables manufacturers to gather real-time data on part dimensions and quality directly at the machine tool, ensuring precision and consistency throughout the manufacturing process. AAT3D’s solutions are used by a wide range of industries, including aerospace, automotive, medical device, and electronics manufacturing.

About Nikon Industrial Metrology

Nikon provides a variety of products, services, and solutions worldwide, based on advanced opto-electronics and precision technologies cultivated during the company’s more than 100 years of history. The group continues to create new values that contribute to improvement of quality of life and manufacturing in a wide variety of forms. Nikon’s Industrial Metrology Business Unit (IMBU) delivers integrated, optimised, ultra-high precision solutions that are not only customised and cost-effective but also work extremely well as soon as they are implemented. A recent development under Nikon’s Digital Manufacturing banner is closer cooperation between IMBU and the corporation’s Digital Solutions Business Unit (DSBU), which has launched a series of optical additive and subtractive manufacturing solutions for processing a wide variety of materials to sub-micron surface finish. www.industry.nikon.com